Technical documentation

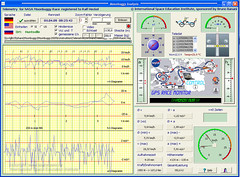

Today, the new differential gear of the Moon Buggy on the intec subcontracting was presented in Leipzig. The German engineering companies and Madler IGUS had accompanied the 5-year development of this transmission with material. The development was supported by an international team of students (14-18 years old), headed by a young engineer from Moscow (22) and the auspices of the "International Space Education Institute" conducted in Leipzig. Involved in the production and processing of individual parts to the CAD templates were, the Saxon company: Machine Shop Günter Jacob, Wittenbecher engineering, mechanical engineering Aischmann, Holl GmbH and 1st Mould. The development was funded by the association on its own power with the assistance of Messrs. Bruno Banani and the Space Hotel Leipzig. The 5 - year development was primarily based on the high standards required for success in the NASA Moonbuggy Race. There were 16 high performance races recorded with a variety of data sensors and data telemetry. Through the data collection we were able to significantly optimizes the transmission in three generations. There was a scientific circle between development - test results - evaluation and development. During this time, two team members completed their preparatory course with this subject in high school with top grades. At the INTEC-Subcontracting Fair in Leipzig chief designer Evgeniy Zakutin (ISEI) and the producers Ronny Hessel (turnery Günter Jakob) and Siegfried Aischmann (Aischmann engineering) presented the new Moon Buggy transmission. At the stands of Mädler and IGUS hit the freshly assembled core of successes. It was remanded to the director of the Fa IGUS, Mr. Ing Thomas White. This gearbox is part of the 6th manus ® competition for plastic plain bearing applications of the Fa. IGUS and will be presented to the public on April 10th 2013 at the Hanover Fair. The special features of the rugged and lightweight transmission include the use of maintenance-free polymer bearings, the use of reinforced carbon fiber by injection of molding and of course the young average age of the developer - 17 years. The production-ready gear is now has a variety of applications and is not just for NASA's Moonbuggy Race, but also a design competition for high-performance teams. So it is particularly suitable for light electric vehicles, electric quads, trikes, Ped-Mobile, wheelchairs and automatic guided industrial mobile equipment. It is fit to use up to a torque of 300 Nm (ca. 220 Pound-force foot). The long and difficult road to a flawless product requires all teamwork, integrity, excellence, ideas, dedication and patience. Here is a summary of annotated images with large photos of the laborious development in 5 years. All those involved have grown so beyond itself:

Application for the manus®-contest (PDF, 24 MB),

highschool student (age/participation in years): college students and young engineers: supervisors/idea/financiation/correktur: supporting people (materialdonators & help): and many other privat persons and handicraft workers, who are supporting the Moonbuggy-Project in Germany supporting industrial companies (materialdonators & help): supporting companies (money donations): |

|||

|